Photo of the day: Crew 208 Photo of the Day.jpg

Operations Report – March 28th

SOL: 0

Name of person filing report: Dean Jin

Non-nominal systems: Generator

Notes on non-nominal systems: Radiator hoses and alternator need replacement on the generator. A contractor has been arranged to make these repairs within a few days.

Generator (hours run): 13.5

Solar – SOC 79% @ 1900 (before David turned on generator for the night)

Diesel Reading – 50%

Propane Reading – 60%

Ethanol Free Gasoline – 2 gallons

Water (auxiliary tank) – 0 gallons (Note: Not in Use)

Water (static tank) – 138 gallons

Auxiliary to Static tank transfer – No

Gallons transferred: 0

Water in GreenHab – 124 gallons

Static to Loft Pump used – Yes

Water Meter: 142186.3 gallons @ 1445

Toilet tank emptied: Yes

Deimos rover used: No, not functional

Hours: N/A

Beginning charge: N/A

Ending charge: N/A

Currently charging: N/A

Sojourner rover used: ASSIGNED TO DIRECTOR

Hours: N/A

Beginning charge: N/A

Ending charge: N/A

Currently charging: N/A

Spirit rover used: No

Hours: 85.1

Beginning charge: 100%

Ending charge: 100%

Currently charging: No – Charging Complete – Plugged In

Opportunity rover used: No

Hours: 54.9

Beginning charge: 100%

Ending charge: 100%

Currently charging: No – Charging Complete – Plugged In

Curiosity rover used: No

Hours: 84.7

Beginning charge: 100%

Ending charge: 100%

Currently charging: No – Charging Complete – Plugged In

Notes on rovers: Not Used

ATV’s Used: (Honda, 300, 350.1, 350.2, 350.3) N/A

Reason for use: Not Used

Oil Added? No

ATV Fuel Used: 0 Gals

# Hours the ATVs were Used today: 0

Notes on ATVs: None

HabCar used and why, where? Not Used

CrewCar used and why, where? Not Used

General notes and comments: Nothing to report

Summary of internet: Nothing to report

Summary of suits and radios: EV suits normal, all batteries read > 12.5 volts

Summary of Hab operations: Checked SOC of electrical system as follows:

0800 SOC 100%, generator turned off by David

0900 SOC 98%, generator off

1430 SOC 84%, generator off

1900 SOC 79%, generator turned on by David

Summary of GreenHab operations: Nothing to report

Summary of ScienceDome operations: Nothing to report

Summary of RAMM operations: Nothing to report

Summary of any observatory issues: None (Note: observatory is closed)

Summary of health and safety issues: None

Greenhab Report – March 28th

Crew 208 GreenHab Report – 28-MAR-2019

GreenHab Officer: Julielynn Wong

Environmental control: Ambient with door open (door opened at 0830, re-opened at 1600, noted to be closed at 1850)

Shade cover of 80% was installed by David this morning.

Average temperatures: 30 degrees Celsius

Low: 24 degrees Celsius

High: 39 degrees Celsius

Hours of supplemental light: None

Daily water usage for crops: 4 gallons

Water in Blue Tank—124 gallons

Time(s) of watering for crops: 0930; 1600

Changes to crops: None

Narrative: At 1600 and 1850, door was noted to be blown shut due to high winds.

Harvest: None

Support/supplies needed: None

Sol Summary – March 28th

Sol: 0

Summary Title: There’s No Place Like Home

Author’s name: Julielynn Wong

Mission Status: Nominal

Sol Activity Summary:

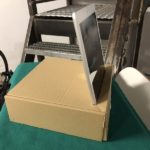

Crew 208 continues 3D printing in the Hab for our thoracentesis training study. One of our 3D printers is not operational.

The following items were identified as useful to 3D print at MDRS:

iPad or iPhone stand to take timelapse videos

COM continues to fulfill GHO duties. XO continues to fulfill ENG duties.

COM has revised activity schedule for Crew 208 based on timelines observed with Crew 207.

Look Ahead Plan: Continue 3D printing in Hab. XO to pick up Crew 208 GHO in GJT on Sol 1. Rest of Crew 208 arrives on Sol 2.

Anomalies in work: None

Weather: Sunny with high winds

Crew Physical Status: Nominal

EVA: n/a

Reports to be filed: Operations, Greenhab

Support Requested: None

Mission Summary – Crew 207

Crew 207 Medical Makers – Mission Summary

Commander: Julielynn Wong

Executive Officer: Dean Jin

Health & Safety Officer: Kevin Ho

Scientist: Tiffany Ni

Engineer & Astronomer: Tom Baldwin

GreenHab Officer & Journalist: Diane Rothberg

Medical Makers is a global community of innovators, patients, and healthcare providers who use low-cost technologies to make sustainable solutions to save lives, time, and money. Medical Makers host Medical Make-A-Thons worldwide to crowdsource low-cost, high-quality, life-changing 3D printable solutions for 3D4MD’s digital library.

Our MDRS mission dates were from March 16, 2019 to March 27, 2019. We completed a total of 7 EVAs.

Crew 207 Medical Makers Projects at MDRS

Project #1: Printing open-source designs of lower-cost labware to provide more accessible STEM learning opportunities for the 90% of the world’s population who do not have a university education

Crew 207 Medical Makers Scientist and HSO 3D printed 17 labware items and tested their functionality in the MDRS Science Dome. Many of these print files were prepared by 34 participants of the inaugural MMYMM Medical Make-A-Thon hosted at Keyano College in Fort McMurray, Alberta on March 10, 2019.

On March 22, Crew 207 Medical Makers experienced a brief power interruption at MDRS while 3D printing a slide drying rack out of biodegradable plastic. Fortunately, our 3D printing system was able to continue and finish printing this functional item after power was restored.

Project #2: Demonstrating the technical feasibility of bike-powered 3D printing by six Martian analogue astronauts — who are following the International Space Station cycling ergometer schedule — to empower the 1 billion people without access to electricity to use portable 3D printing technologies and biodegradable plastic filament

Crew 207 Medical Makers showed that a renewable, green energy source can power a 3D printer to use biodegradable plastic to make an ISS medical inventory item, a customized medical device that was previously printed on the ISS, and a spare part for a self-replicating replicator on-site during a Mars analogue mission.

Six crew members cycled for 1 hour per day for a total of 2 days per crew member on a bicycle to charge a battery that was used to power the 3D4MD 3D printing system. Crew 207 Medical Makers used this bike-powered battery to 3D print a tongue depressor and customized mallet finger splint out of food-safe, biodegradable plastic and a replacement knob for the 3D printer’s LCD out of recyclable, biodegradable plastic.

Crew 207 Medical Makers data has been compiled and been transmitted home for analysis and manuscript preparation. Data collection will continue with Crew 208 Medical Makers.

Project #3: Identifying essential items that can be 3D printed on demand locally to save lives, time and money for the 3.75 billion people who live in remote or rural areas, the 136 million people who require humanitarian aid, and astronauts on long space missions

Crew 207 Medical Makers identified 30 items that would be useful to 3D print at MDRS. These items will be distributed as design challenges to Crew 208 Medical Makers, Medical Make-A-Thon participants and 250+ Medical Makers in 10 countries.

Crew 207 Medical Makers 3D printed the following items on demand locally at MDRS:

- Coat hanger

- Bag clip

- Stackable storage bin

- Funnels (3 sizes)

- Soil sieves (2 sizes)

Crew 207 Medical Makers Journalist, Diane Rothberg, observed that it would be helpful to use a clip to re-seal our opened bags containing flour and brown sugar. On March 20, Crew 207 Medical Makers Commander, Dr. Julielynn Wong, reached out to members of the Medical Makers YHM Chapter who have been re-designing and testing a watertight, reusable, 3D printed pouch clamp for stoma patients. They immediately uploaded their print files to the Medical Makers shared drive and Crew 207 Medical Makers was able to 3D print and use their design to re-seal a food bag at MDRS on the same day.

On March 23, Crew 207 Medical Makers Scientist, Tiffany Ni, used an open-source design and freeware to create and 3D print customized funnels matching the dimensions of 3 different funnels found in the Science Dome at MDRS. By creating 3D printable designs of useful items at MDRS, Medical Makers can add files to 3D4MD’s digital archive to benefit remote and low-resource communities in need.

Crew 207 Medical Makers also 3D printed the following 3D4MD catalog items out of biodegradable, washable plastic:

- High-quality, safe, UNICEF early childhood education kit items for children caught in conflict zones or humanitarian emergencies

- Low-cost, high-quality, 3D printable United Nations Comprehensive Sexuality Education Curriculum teaching models for voluntary medical male circumcision, a procedure that has been shown to reduce HIV transmission by 60% in high-risk areas

- A special Mars edition of “Lego-style” Braille Bricks to help educate the 1 billion children and adults who are visually impaired

- Medical supplies that meet FDA and Health Canada guidelines to diagnose and treat an ill or injured astronaut on a long space mission

- Low-cost and high-quality spare parts and accessories for our self-replicating “Star Trek Replicator”

Project #4: Using reusable, personalized 3D printed straws made out of food-safe biodegradable plastic to conserve water at MDRS and reduce the amount of plastic waste in landfills and oceans

Crew 207 Medical Makers observed that each individual crew member was using multiple cups per day because the cups provided at MDRS are identical in design and color. This meant that the crew had to wash extra cups every day. This led to an increased consumption of water which is a limited and valuable resource at MDRS. By March 21, all six crew members were using 3D printed colored straws to identify their personal cups for re-use all day. This helped conserve our water resources at MDRS.

Project #5: Testing a low-cost, high-fidelity, 3D printed thoracentesis trainer designed to allow healthcare trainees and professionals to attain and maintain life-saving surgical skills to serve the 5 billion people who lack access to safe, timely, and affordable surgical care

Five crew members with no prior surgical training used a porcine and 3D printed thoracentesis trainer to acquire life-saving procedural skills to decompress a tension pneumothorax on a simulated patient. Three performance metrics were measured; performance score, procedure time and learner’s confidence. Data collection will continue with Crew 208 Medical Makers.

Three out of seven components of 3D4MD’s thoracentesis trainer were successfully 3D printed at MDRS during the Crew 207 Medical Makers mission. The remaining four components will be 3D printed during the Crew 208 Medical Makers mission.

Project #6: Piloting drones to survey and print a 3D map of MDRS and the surrounding Mars-like terrain

Crew 207 Medical Makers Part 107 pilots used a camera drone to complete four pre-programmed drone mapping flights of MDRS and the surrounding region. Map processing and 3D printing will continue with Crew 208 Medical Makers.

Project #7: Testing a new drone controller designed by a retired NASA astronaut, physician, explorer, pilot, and inventor

Crew 207 Medical Makers flew a camera drone to conduct an outdoor inspection of the MDRS Habitat roof during a simulated emergency. Four novice drone pilots compared the performance of a traditional and new drone controller when flying in a square pattern (60 feet for each side) at an altitude of 20 feet. Post-flight surveys were completed and qualitative feedback was obtained. Preliminary feedback has been submitted to the drone controller manufacturer. More flight testing is planned for Crew 208 Medical Makers.

Acknowledgements

Crew 207 Medical Makers is grateful for the financial support of Dr. Robert Milkovich and Mrs. Marijana Milkovich, the University of Toronto Collaborative Specialization in Resuscitation Sciences – Institute of Medical Sciences Travel Award, Ron Rivkind at Filaments.ca, and Schulich Leader Scholarships, Canada’s most coveted undergraduate STEM scholarships. Our MDRS projects were also made possible thanks to Atila Meszaros, David Mateus, and Shannon Rupert at the Mars Desert Research Station, Dean Vincella Thompson at Keyano College, Marius Kintel at OpenSCAD, Dr. Scott Parazynski and George Guerrero at Fluidity Technologies Inc., Jack McCandless, Jade Bilkey, Crew 208 Medical Makers, and members of the Medical Makers YGK, YHM, YKF, YMM, YVR, YYT and YYZ Chapters.

You must be logged in to post a comment.